Manufacturing

Raw Material

The manufacturing of high quality knives, like ours, begins with the selection of the highest possible purity diamonds with a regular crystal structure. The crystal orientation of the diamond that we have chosen permits a final polishing parallel to the cutting edge, which gives you an extremely sharp, scorefree, durable cutting edge.

Precision in Grinding and Polishing

Our precise pre-grinding and polishing techniques assure you the perfection in a diamond knife that you expect. Each one of our stones is ground strictly in accordance with its structure, with an accuracy of +/- 2 degrees being maintained in the crystal axis.

In contrast to the methods of others our diamond knives are ground parallel to the cutting edge. Some of the reasons for doing so are as follows:

- The cutting edge life of a diamond tool used for processing a tough metal such as beryllium bronze can be appreciably lengthened, if the diamond is oriented in such a way, that the grinding direction is at a right angle to the subsequent working direction. If we wish to apply this knowledge to the manufacturer of diamond knives, then the grinding direction will be parallel to the knife cutting edge. This is crucial in the cutting of bone or metals, for example.

- The diamond knife cutting edge is formed from the polished surface which is turned towards the trough and the ground surface which forms the clearance angle with the block. Since the sections pass over the side turned towards the water, this surface is subject to much greater use than the clearance angle surface, and if it has been badly polished, the areas with polishing ridges in the cutting edge give rise to stripes and streaks in the sections, some more visible than others.

The same thing would occur if we turned the ground surface towards the water and its grinding ridges were not exactly parallel to the cutting edge. It has been demonstrated that the steeper the grinding ridges are to the knife cutting edge, the more pronounced is the formation of stripes in the sections. According to this, grinding or polishing at right angles to the cutting edge would represent an extreme case.

Knives that have been supplied by us in perfect condition have come back to us after complaints and have been found to be cutting with streaks, even though there was no damage visible under the microscope.

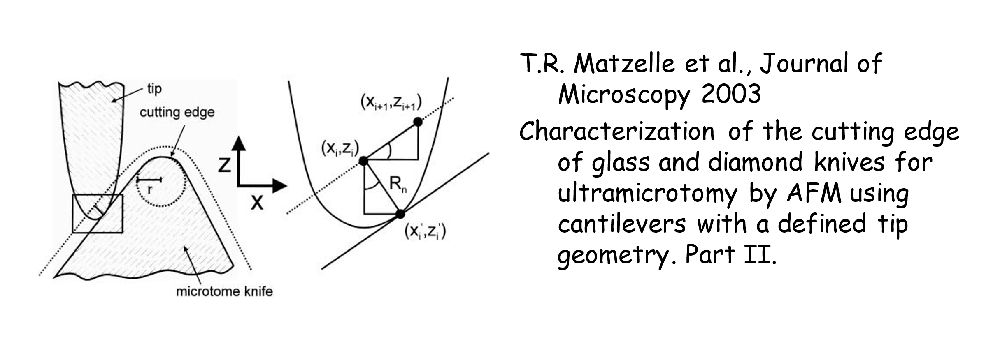

The Cutting Edge

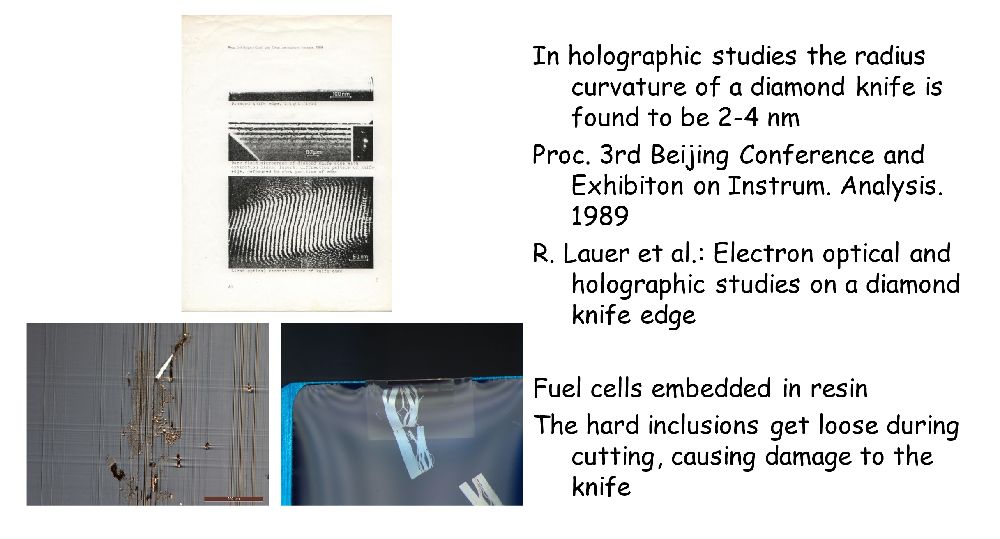

The sharpness of a DiATOME knife edge can not fully be shown in a light microscopy photograph, however, it has been shown that the radius of curvature of our knives is less than 2-4nm.*

Quality Control, Optical Checking, and Section Testing

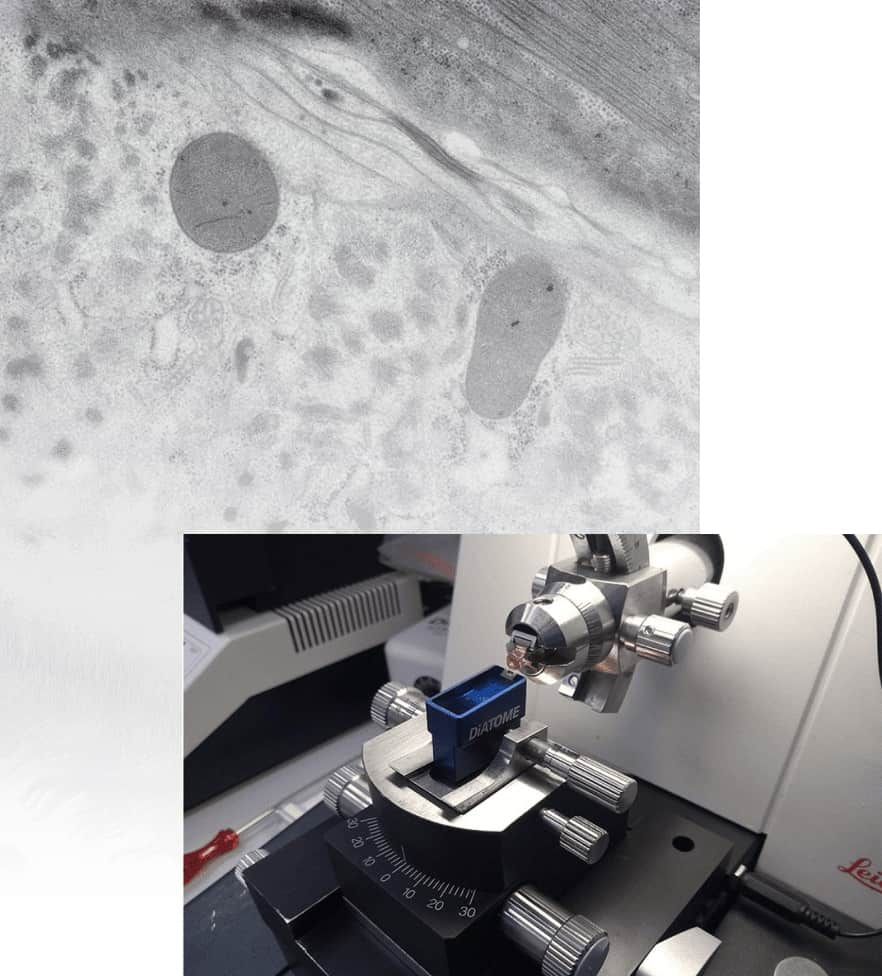

The final step before any of our knives leave the plant is our own extensive testing that each knife, new or resharpened, is put through. Only if these knives perform successfully will they be sold. During the polishing process the edges of the knives are inspected at 500 to 1000x magnification. Very small irregularities that could not be found by light microscopy are detected during the sectioning test in accordance with the range of the different knife types (sections are checked by light and electron microscopy).

Only knives that cut perfectly over this range are accepted for delivery to the customer.